Great Applications

Low time on bottom and daily footage due to:

- Interbedded formations – hard to less hard or less hard to hard

– Frequent trips for a bit “type” change - Hard rock (and/or) abrasive rock

- Frequent trips for bit wear – short life

- Anywhere Impreg Bits are run

- Trouble maintaining verticality?

– High WOB causing deviation

– Formations dips or trends, crossing faults

– Running motors or Rotary Steerable or VertiTrak or light weight - Drilling dynamics problems – Slip-Stick, Bit whirl

– Poor BHA component reliability causing trips

Other Benefits to Consider

- Will typically reduce drill string torque ~ 20%

- Will reduce drill string wear in abrasive formations

- Drills with low WOB and Torque at Bit

- The bit should last the entire interval

- Works with any mud type with a YP > 16

Engaging Particle Drilling Technologies

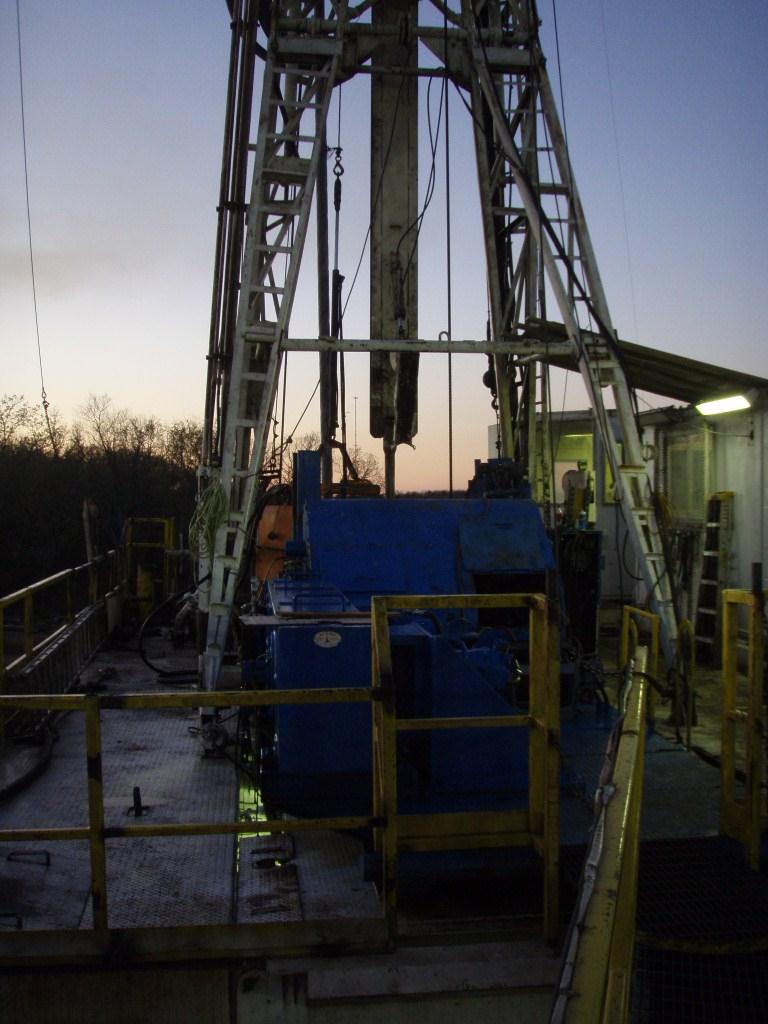

Particle Drilling Technologies is chartered to rapidly drill formations and drilling intervals that have very high cost using conventional drilling tools by using its proprietary Particle Impact Drilling (PID) system. The key to the drilling is impacting the bottom hole with large volumes of hardened steel particles which removes millions of small volumes of rock per minute which add up to very high rates of penetration in hard, deep, difficult to drill formations. The PID systems are made up of a novel particle injection trailer, particle storage, recovery and dispersal skid, operations control trailer and patented drilling heads. The system is independent of the rig operations and can be quickly isolated if necessary. The systems are operated by skilled crews that know the equipment and can be safely operated.

The PID drilling system can be hired, rented, or leased, through several options:

- Daily rates, special technology needs for a particular application or interval, drilling mud and its maintenance, drilling bits, special oilfield tools if needed, PID equipment mobilization, and other unique needs for the drilling application are all usually set forth in a standard IADC service agreement and/or contract.

- Long term agreements and contracts for the of PID equipment and crews.

- Exclusive use of PID equipment and services for in field development drilling

- A shared cost of realized savings for a drilling application with a percentage of the savings between conventional drilling and PID drilling being awarded to PDTI.

- A percentage of the realized production from a well that was drilled partially by PID

Particle Drilling Technologies has a staff of very experienced personnel with a great deal of knowledge in various areas of drilling and producing oil and gas wells. Consulting services on world-wide specific drilling applications, especially difficult and expensive to drill geological formations (ultra-hard, interbedded hard and soft, deep and very slow drilling rate) or intervals, are available.

Consulting on drilling boreholes in previously non-drillable formations due to costs of conventional drilling is done routinely and aimed at expanding new markets for oil and gas.